Concrete Block Machine Pallets

Pallets for Concrete Block Machine

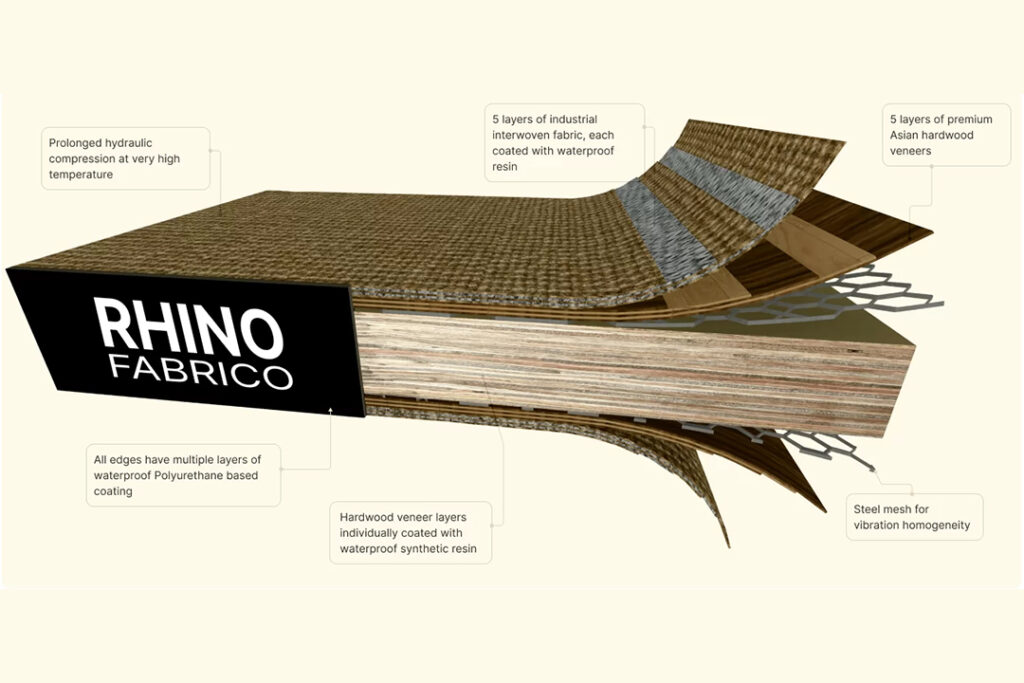

RHINO concrete block machine pallets are manufactured from high-quality densified hardwood.

This hardwood is FSC certified ensuring all concrete block machine pallets are made from sustainable forests.

After treatment with waterproof resin, they are hydralucally pressed under high pressure and temperature to create extremely durable pallets for concrete block machines. These pallets for concrete block machines, also known as production boards, are single solid pieces, with no joints or gaps whatsoever.

RHINO concrete block machine pallets are reinforced with dual steel mesh which adds durability and strength of these production boards. production.

Concrete Block Machine Pallets

RHINO concrete block machine pallets are designed in a unique way ensuring that hardwood fibres are structured as reinforcing elements. This structure gives extreme strength and durability that can far outlast many other materials.

Our manufacturing process eradicates the problems experienced from concrete blok pallets manufactured with other materials like softwood, pinewood, plastic PVC etc..

This advancement is achieved through scientific design and advanced manufacturing processes employed to create RHINO hardwood concrete block machine pallets.

From the rust and heavy weight of steel, to the pollution created by PVC pallets, the sturdy hardwood used to create our RHINO Hardwood pallets has overcome such issues.

With a highly densified structure, vibration transmission to the green concrete is optimised resulting in reduced cycle time, and consequently higher production.

REFURBISHABLE DENSIFIED HARDWOOD PALLETS

Not only are our densified hardwood pallets for concrete block machine durable enough to outcompete steel pallets, they’re also refurbishable so they can be used for even longer. This maximises your investment and makes RHINO Composite Pallets the easy choice for you.

Wondering how refurbishing works? Simply reach out to us at the end of the pallets’ long service life and we will organise a refurbish at the factory for you. The pallets will then be shipped back to you for further use.

But before refurbishing, did you know that our pallets can also be sanded back up to 3 times, in-house, to refresh them?

Why Choose RHINO Hardwood Pallets for Concrete Block Machine

FREQUENTLY ASKED QUESTIONS

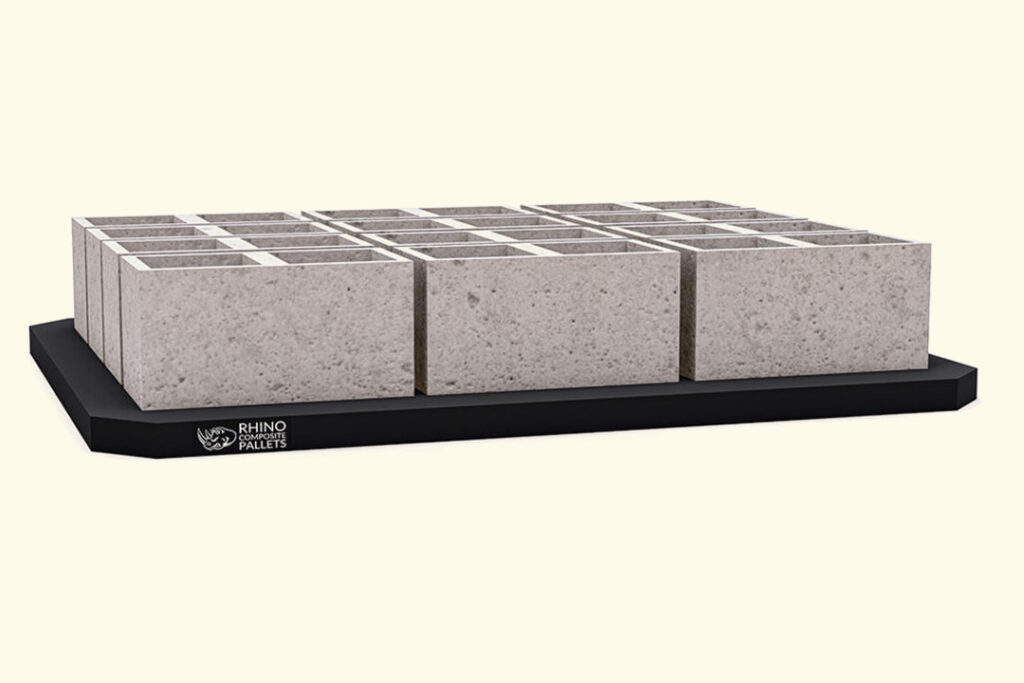

A concrete block machine pallet is a large rectangular production board used in the manufacturing of concrete blocks, pavers, kerbstones and bricks. The semi-wet concrete in a block machine is formed into the shape of a concrete block or paver on a pallet. Then, this pallet is used to transport wet blocks into a curing chamber, allowing the block to dry into uniform shapes.

A pallet can be made from a variety of materials such as hardwood, softwood, steel, PVC and GMT. These options will be further explored below.

Pallets come in all different dimensions depending on the machine they will be used in. Contact us to discuss sizes that suit you.

Pallets are necessary in the manufacturing process for allowing the wet blocks to dry and form uniform shapes, as well as to transport them during this process.

Pallets can be stacked one on top of the other in vertical racks in the curing areas to save warehouse space. Without pallets, the concrete block machines would not have anywhere to manufacture the blocks nor be able to transport them within the plant quickly in bulk.

MASA HESS ILMAR POYATOS TIGER QUADRA TECHMATIK KVM

The earliest production pallets for concrete block production were manufactured using softwoods like pine, fir and poplar. While they are cheap pallets and easily available, they do not last very long in the highly abrasive environment of a concrete block factory, warping easily due to ambient humidity and must therefore be replaced fairly regularly, sometimes every year or two in especially humid regions

Pallets for Concrete Block Machine

Beginning from its impeccable design of durability to its positive environmental impact, our RHINO production boards introduce a material with outstanding characteristics which outshine any other concrete block machine pallet in the market today.

RHINO production boards can be used with a clean conscience since it employs FSC certified plantation hardwood and no jungles were damaged for procuring this hardwood.

RHINO Production Pallets for Concrete Block Machines can be used in all types of Concrete Block and Paver machines.

Typical examples can be the following :

- Concrete Block Machine Pallets for MASA

- Concrete Block Machine Pallets for HESS

- Concrete Block Machine Pallets for HAREX

- Concrete Block Machine Pallets for ZENITH

- Concrete Block Machine Pallets for KVM

Product Range

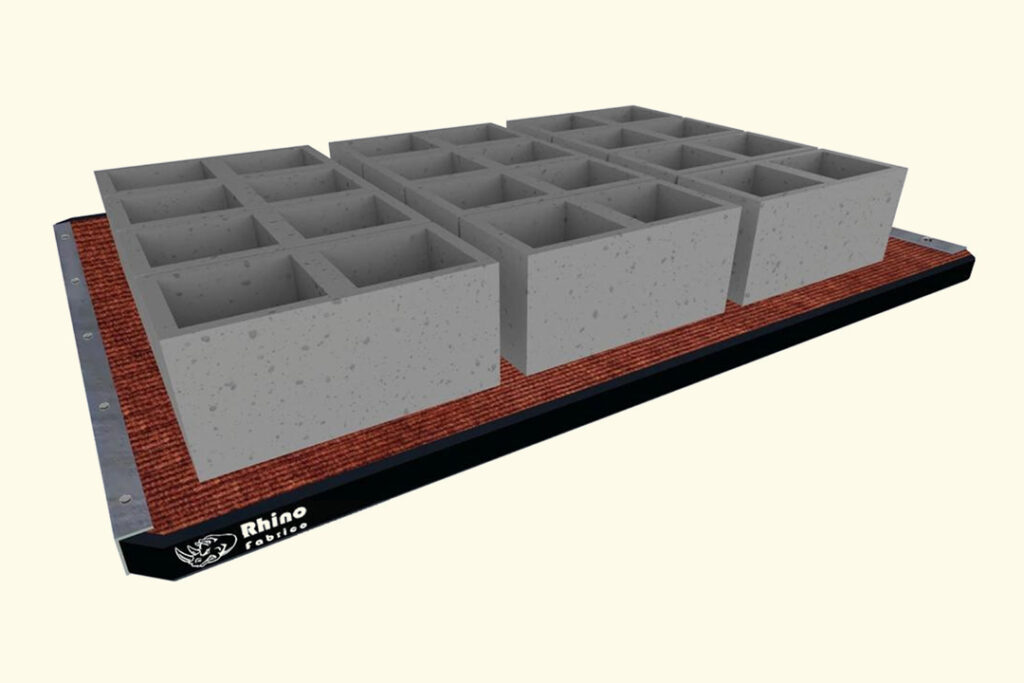

RHINO FABRICO

The top and bottom surfaces of this board are protected by five layers of industrial fabric. The fabric is impregnated with high strength thermosetting waterproof resin.

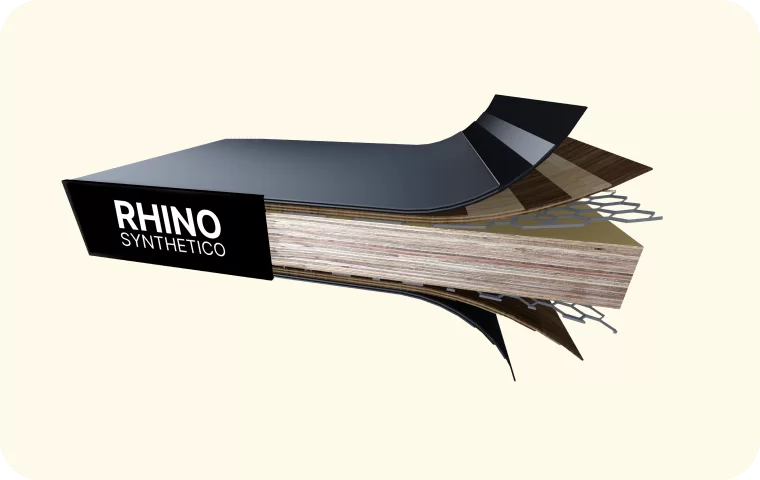

RHINO SYNTHETICO

The top and bottom surfaces of this production board are protected by multiple layers of synthetic films coated with high strength thermosetting waterproof resin.

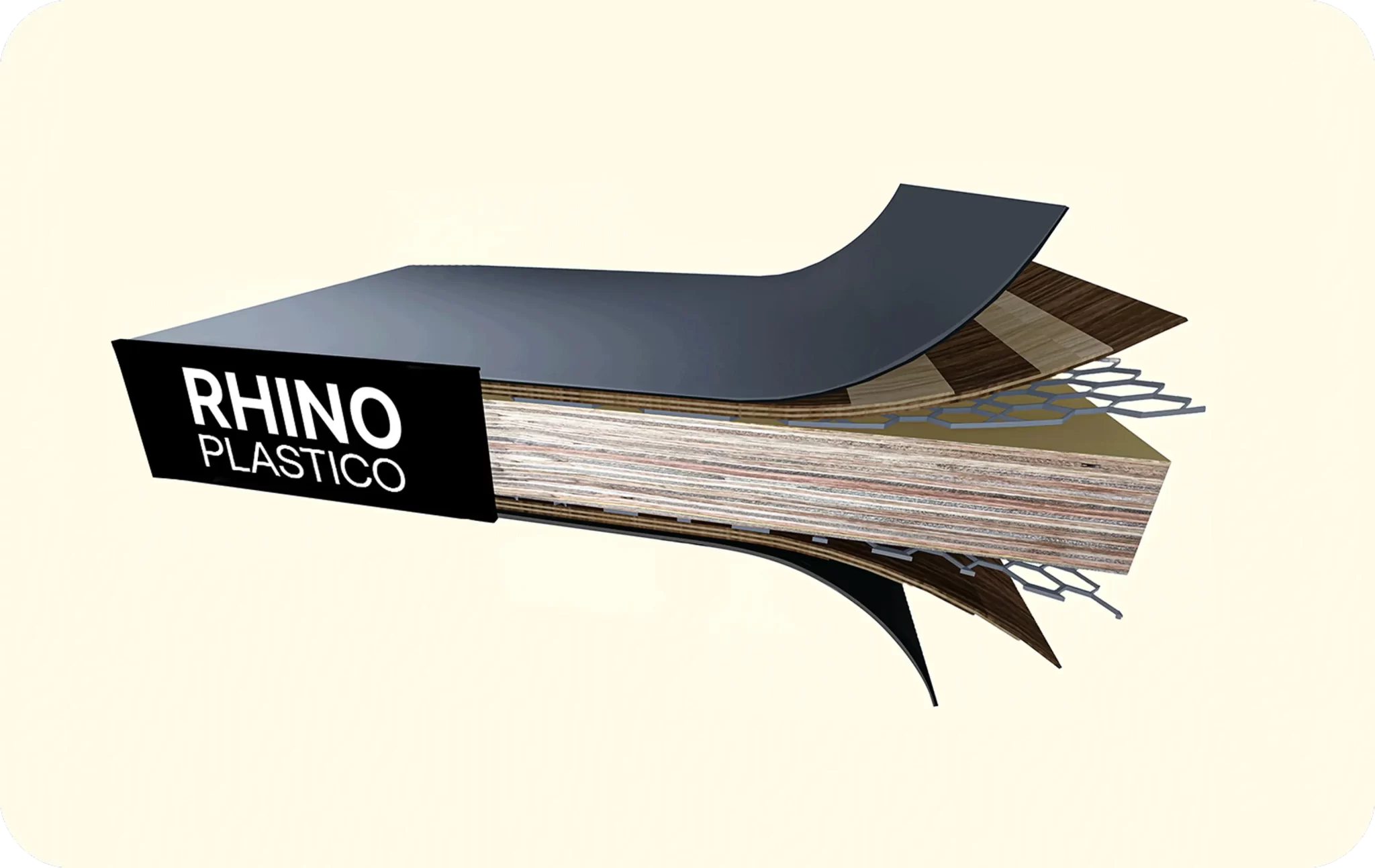

RHINO PLASTICO

The top and bottom surfaces of Rhino Plastico are reinforced with a thick sheet of polypropylene.

Ready to try a sample?

Contact Us

Please contact us by filling out the form below and we’ll reach out to you within 1 business day.